Choosing the Top 5 Manufacturers for Best Slat Wall Acoustic Panels Worldwide

In recent years, the growing demand for effective noise control solutions has led to an increase in the popularity of Slat Wall Acoustic Panels, known for their aesthetic appeal and superior sound absorption properties. According to a report by MarketsandMarkets, the global acoustic panels market is projected to reach USD 1.17 billion by 2024, growing at a CAGR of 5.7% between 2019 and 2024. This surge in demand highlights the importance of selecting high-quality manufacturers to ensure optimal performance and compliance with industry standards. In this blog, we will explore the top five manufacturers of Slat Wall Acoustic Panels worldwide, emphasizing their manufacturing strengths and commitment to quality that positions them at the forefront of the export market, particularly from China—a hub for efficient and innovative production methods.

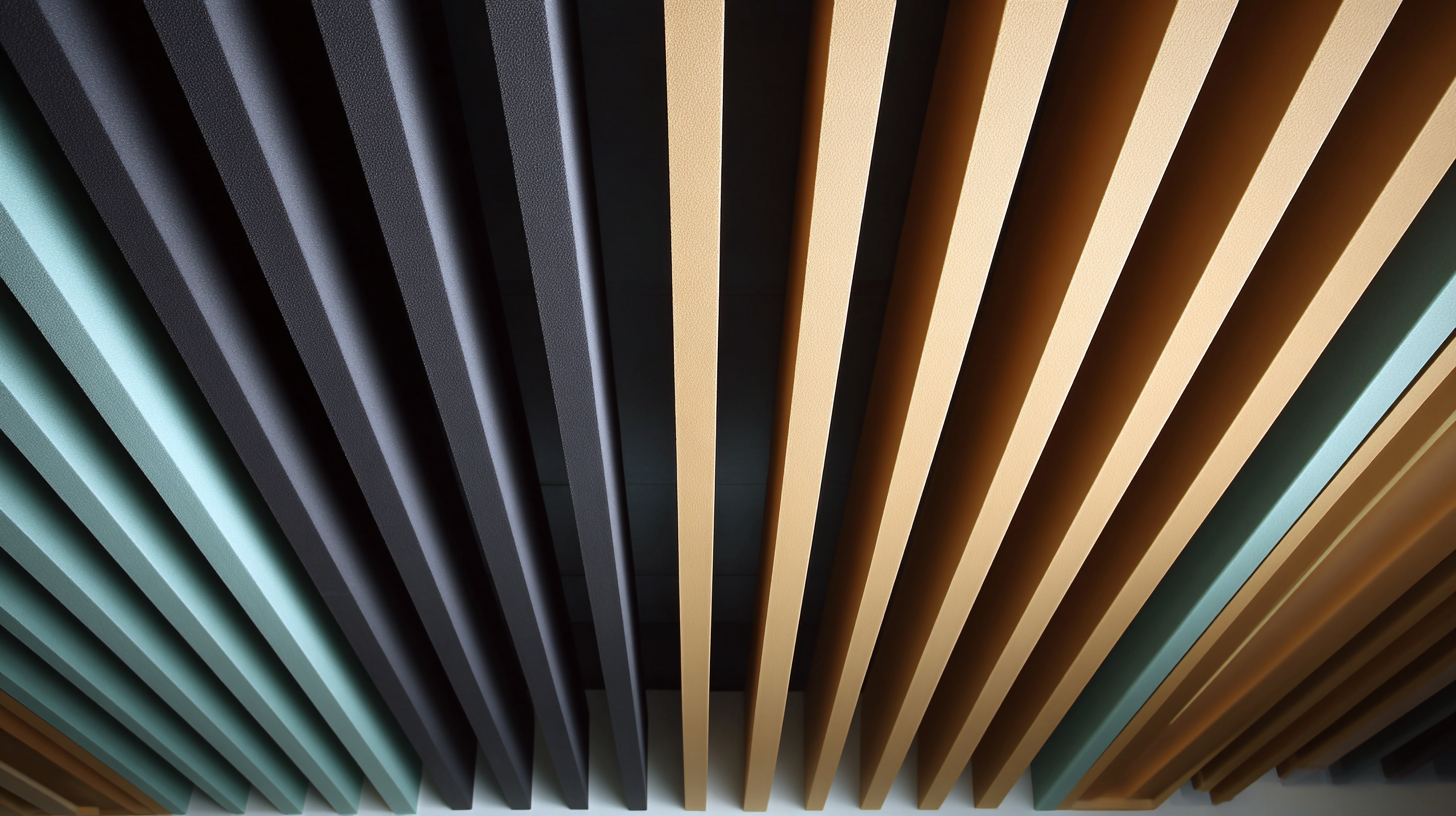

Understanding Slat Wall Acoustic Panels: Benefits and Applications

Slat wall acoustic panels are rapidly gaining popularity due to their versatility and numerous applications in various environments. These panels serve not just as aesthetic enhancements to interior spaces, but also as effective sound-absorbing solutions. Made from materials like wood and bamboo fibers, slat wall panels leverage the natural properties of these sustainable resources to minimize noise disruption in homes, offices, and public venues. The unique slat design not only breaks up sound waves but also adds a modern touch to interior designs, making these panels an attractive choice for both functionality and decor.

The benefits of slat wall acoustic panels extend beyond mere aesthetics and sound control. Their lightweight and durable characteristics make installation and maintenance hassle-free, catering to both residential and commercial needs. Additionally, brands are now focusing on eco-friendly production methods, aligning with the growing demand for sustainable materials. From creating a calming atmosphere in a busy workplace to enhancing the audio experience in a home theater, slat wall acoustic panels present a powerful solution for sound management while promoting an environmentally conscious approach to interior design.

Key Factors to Consider When Selecting Top Manufacturers

When selecting the top manufacturers of slat wall acoustic panels, several key factors must be considered to ensure a high-quality product that meets specific acoustic needs. One crucial element is the material composition of the panels. According to a report by Acoustical Solutions, panels made from high-density fiberboard (HDF) reduce sound transmission by up to 60%, proving essential for environments requiring significant sound insulation.

Another important factor is the manufacturer's reputation and experience in the industry. A survey conducted by Research and Markets indicated that companies with over 15 years in the acoustic panel market are likely to have the most innovative designs and reliable customer service. Specifically, these manufacturers tend to maintain stringent quality control processes, leading to better acoustic performance and durability.

Finally, customization options offered by manufacturers can greatly influence the effectiveness of slat wall acoustic panels. The Acoustic Society of America emphasizes the benefits of personalized panel designs, stating that tailored solutions can enhance sound absorption performance by over 30% compared to standard models. Therefore, consider these elements when evaluating potential manufacturers for optimal acoustic solutions.

Top 5 Manufacturers for Best Slat Wall Acoustic Panels

This chart illustrates the acoustic panel manufacturing capabilities based on key performance indicators such as sound absorption efficiency, durability, design variety, customer reviews, and market reach.

A Deep Dive into the Best Manufacturing Techniques for Acoustic Panels

When it comes to enhancing sound quality in various environments, the manufacturing techniques of slat wall acoustic panels play a crucial role. Reputable manufacturers utilize advanced technologies such as CNC cutting and precision engineering to ensure that each panel delivers optimal acoustic performance. These methods allow for precise control over panel thickness and spacing, which significantly affects sound absorption properties. It's vital for manufacturers to combine these techniques with high-quality materials, such as premium wood and specialized soundproofing fabrics, to create products that are both aesthetically pleasing and highly functional.

One useful tip when selecting acoustic panels is to consider the specific acoustic needs of your space. Different setups may require varying levels of sound absorption or diffusion. For instance, a recording studio will demand higher sound isolation than a home theater. Additionally, pay attention to the finishes available; choosing a wood grain that harmonizes with your interior design can enhance the overall ambiance while serving its acoustic purpose.

Another important aspect to keep in mind is the panel installation process. Properly installed acoustic panels can significantly enhance their effectiveness. Opt for manufacturers that provide clear installation guidance or professional assistance. This collaborative approach ensures that the panels perform at their best, effectively minimizing sound disturbances and enhancing the auditory experience.

Choosing the Top 5 Manufacturers for Best Slat Wall Acoustic Panels Worldwide

| Manufacturer Location | Manufacturing Technique | Material Used | Eco-Friendliness Rating | Price Range (USD) |

|---|---|---|---|---|

| North America | Injection Molding | Recycled Plastic | 4.5/5 | $50 - $100 |

| Europe | Fiber Bonding | Natural Fibers | 4.7/5 | $70 - $150 |

| Asia | Acoustic Foam Cutting | Polyester Foam | 4.3/5 | $40 - $90 |

| Australia | Wood Lamination | Plywood | 4.6/5 | $80 - $160 |

| South America | Thermal Forming | Hemp Composite | 4.8/5 | $60 - $120 |

Analyzing Market Trends: Leading Manufacturers in Acoustic Panel Production

The global acoustic panel market has seen a substantial growth trajectory, driven by increasing awareness of sound management in various environments. According to a recent industry report, the acoustic panel market was valued at approximately $1.5 billion in 2021 and is projected to reach around $2.5 billion by 2028, reflecting a compound annual growth rate (CAGR) of over 7% during this period. This surge is primarily fueled by the rising demand for better acoustics in residential, commercial, and industrial applications, with industries like entertainment, education, and healthcare leading the charge.

Among the leading manufacturers, players such as Armstrong World Industries and Ecophon have established a strong presence globally, contributing significantly to innovative product development. Reports indicate that these companies focus on eco-friendly materials and customizable solutions to meet diverse client needs. Additionally, the trend towards open office spaces has further highlighted the demand for effective acoustic solutions, prompting manufacturers to expand their product lines with advancements in technology and design. The emphasis on aesthetics combined with functionality is reshaping the market landscape, positioning acoustic panels as an essential component in modern architectural design.

Evaluating Customer Feedback and Performance Metrics for Top Brands

When it comes to selecting the best slat wall acoustic panels, customer feedback and performance metrics play crucial roles in evaluating manufacturers. Reviews from users often highlight the effectiveness of these panels in sound absorption and aesthetic appeal, making them ideal for a variety of spaces. Manufacturers that consistently receive positive feedback tend to focus on using high-quality materials and innovative design, which enhance their product's functionality while also elevating interior décor.

In addition to user reviews, performance metrics such as NRC (Noise Reduction Coefficient) ratings provide valuable insights into a product's acoustic efficiency. High NRC scores indicate superior sound absorption capabilities, and leading brands often leverage these metrics in their marketing strategies to showcase their panels' effectiveness. Companies that combine positive customer experiences with impressive performance data are typically recognized as industry leaders, setting benchmarks for quality and innovation in acoustic panel manufacturing.

-

Phone

-

E-mail

-

wechat

wechat

-

whatsapp

whatsapp